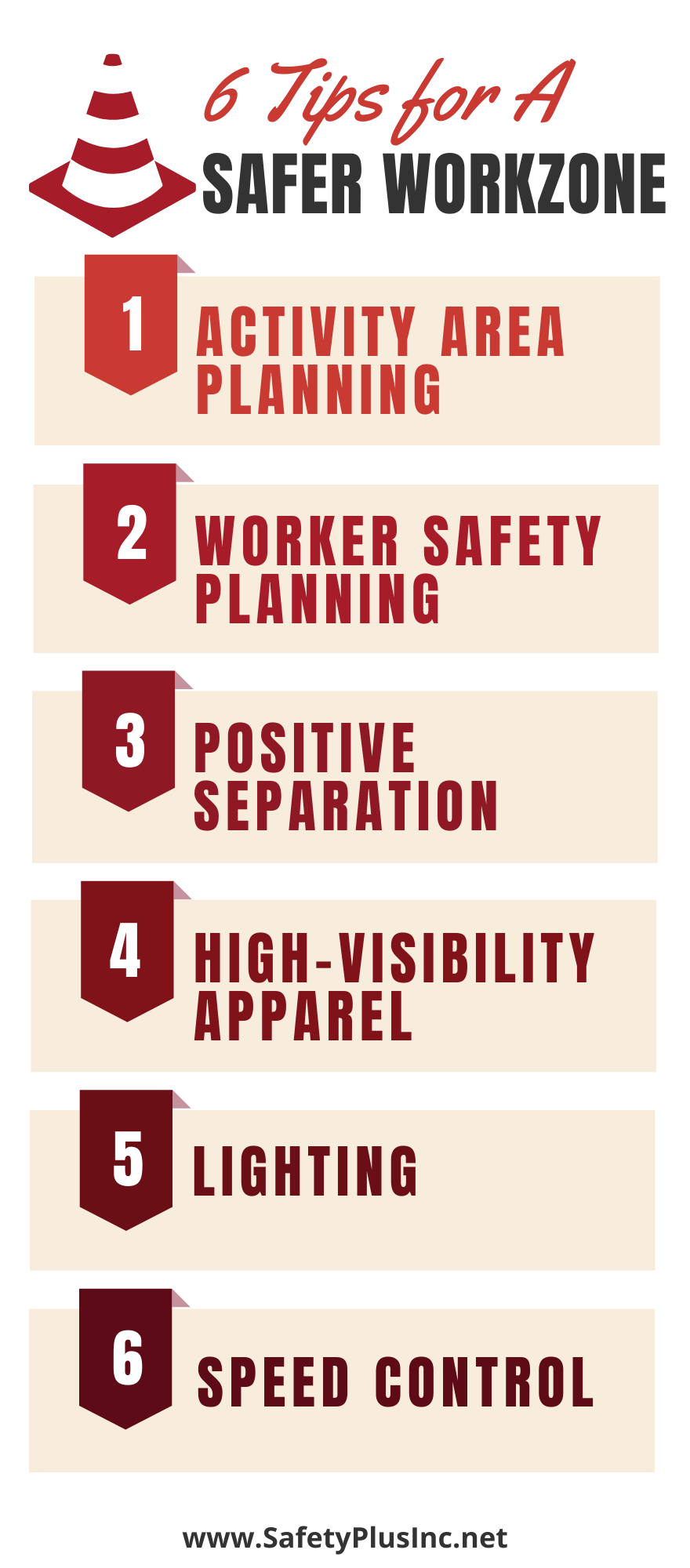

6 Tips for Creating a Safe Work Zone

According to Safer Roads Save Lives (ATSSA), data shows roughly 123,000 work zone crashes occur annually, caused by speed and distractions when approaching and driving through work zones. Therefore, we have gathered six tips and training topics in recognition of National Work Zone Awareness Week.

1. Activity Area Planning:

• Routes should be identified and marked to safely allow workers and work vehicles to enter and exit the workspace safely

• Backing should be controlled by spotters or by other means whenever workers or pedestrians could be present

• Utilities should be located and properly marked to prevent contact by equipment and workers

2. Worker Safety Planning:

A competent safety specialist should adequately address the requirements of OSHA and MUTCD and properly plan, implement, and oversee worker safety. Below are tips to help plan a safe work zone:

• A hazard assessment of the worksite should be conducted to identify worker risks

• Engineering, administrative controls and personal protective measures should be implemented to protect workers from the identified risk

3. Positive Separation of Traffic and Work Activities:

Separating traffic from work activities using temporary traffic barriers, shadow vehicles with truck-mounted attenuators, or similar devices minimizes the risk for both road workers and drivers. Positive separation should be based on the following work zone factors:

• The speed and volume of traffic

• The amount of distance between work zone workers and traffic

• The duration and the type of work operations

• Physical hazards in the construction work zone

• The alignment of traffic lanes going through the work zone

4. High-visibility Apparel:

• All road workers should wear highly visible clothing – worker visibility during dawn or dusk may be enhanced by using fluorescent colored highly visible apparel

• The use of colors such as yellow/green for worker apparel may help differentiate workers from the orange-colored work vehicles, signs, drums, etc

5. Lighting:

Temporary lighting should be used appropriately, especially at night to ensure the following:

• Leading up to and in the work zone – lighting should provide better visibility for drivers and workers to safely transition through the construction work site

• Sufficient lighting should be provided wherever workers are present to make them visible On-foot workers and equipment operators should have at least 5 foot-candles or greater of illumination to help ensure workers are visible

• Glare must be controlled appropriately and not interfere with drivers’ and workers’ visibility of the work zone

6. Speed Control:

To protect the public and workers, it is essential to comply with posted speed limits. The following traffic control strategies can be used to control traffic speeds through work zones, whether or not the speed limit is reduced:

• Establish appropriate speed limits for work zones and properly post regulatory speed limits

• Utilize law enforcement when needed

• Use radar activated changeable message signs

• Employ trained/certified flaggers (under some conditions)

With so many risks to both work zone workers and drivers, precautions should be taken to keep everyone safe during necessary infrastructure projects. There are resources available such as safety management software, safety plans, and best practices to follow that help ensure everyone’s safety in Work Zones. For more information on how to keep your construction workers safe, contact us at Safety Plus Inc.

Recommended Reading

National Safety Month: Reducing Preventable Injuries and Deaths

Every June, National Safety Month reminds us that many injuries and deaths are preventable, whether at work, at home, or on the road. While safety should be a priority throughout the year, this annual initiative gives everyone a chance to slow down, evaluate risks, and take steps to mitigate them. Job site injuries, car accidents,…

The Hidden Costs of Workplace Incidents (and How to Avoid Them)

Workplace incidents can be costly on multiple fronts, from direct costs like medical and legal fees to indirect costs like lost productivity and reputational damage. The ripple effect of a workplace injury or death can last far beyond the incident itself, eating away at profitability and damaging a company’s reputation. However, the right safety measures…

Partner Spotlight: MASC Safety Consulting – Machine Safety & Compliance Expertise for High-Hazard Operations

At Safety Plus, we recognize the critical importance of machine safety and regulatory compliance in industrial operations. To support our clients in achieving these objectives, we are proud to spotlight MASC Safety Consulting, a firm that provides comprehensive safety services tailored to industrial operations. Featured Resource: Comprehensive Machine Safety Services Available Through Our Partner Network…

5 Things We Learned at SEAA 2025

Reflections about trends in the steel erection industry from Safety Plus’s attendance at the Steel Erectors Association of America’s Convention and Trade Show in Pittsburgh The 2025 SEAA Convention & Trade Show in the Steel City of Pittsburgh was nothing short of inspiring! Safety Plus was humbled to sponsor and exhibit at this event for the…

SAFETY MANAGEMENT SIMPLIFIED

Prevent Tragedy and Scale Effectively by Making Safe Work Efficient